Most sub-surface pipe is made of metal or reinforced concrete. There are millions of miles of pipeline running underground across America, and in every developed nation on Earth. A lot of the piping we depend on in the U.S. is aging. Much of it needs to be replaced. Because traditional metal and concrete piping is heavy and is fabricated in short sections, it is very labor intensive and expensive to replace.

Now, there is a better and much cheaper way of building or replacing an existing pipeline.

Civil Engineering Professor Mo Ehsani from the University of Arizona has developed a system that allows the fabrication of lightweight piping on site using a combination of honeycombed aerospace plastic and resin-impregnated, carbon fiber wrap. Ehsani's new technology - he calls it InfinitiPipe - can be scaled to produce piping of the size and strength needed to meet different applications. Because the process can go on more or less infinitely, the joints that cause traditional piping infrstructutre to breakdown are mostly eliminated.

|

| Professor Mo Ehsani with InfinitiPipe |

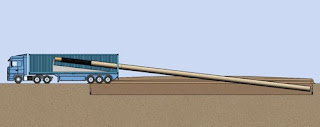

Ehsani invisions mounting the machine that synthesizes the Infiniti pipe on a trailer truck, allowing the piping to be produced right on site, when and where needed.

|

| Truck mounted InfinitPipe synthesis |

The issue now is whether or not the government agencies in charge of ovcerhauling our crumbling sewage and potable water systems will embrace this new technology. The people that make concrete and steel pipe will likely resist such change, despite the cost and safety benefits InfinitiPipe could bring to every community.

No comments:

Post a Comment